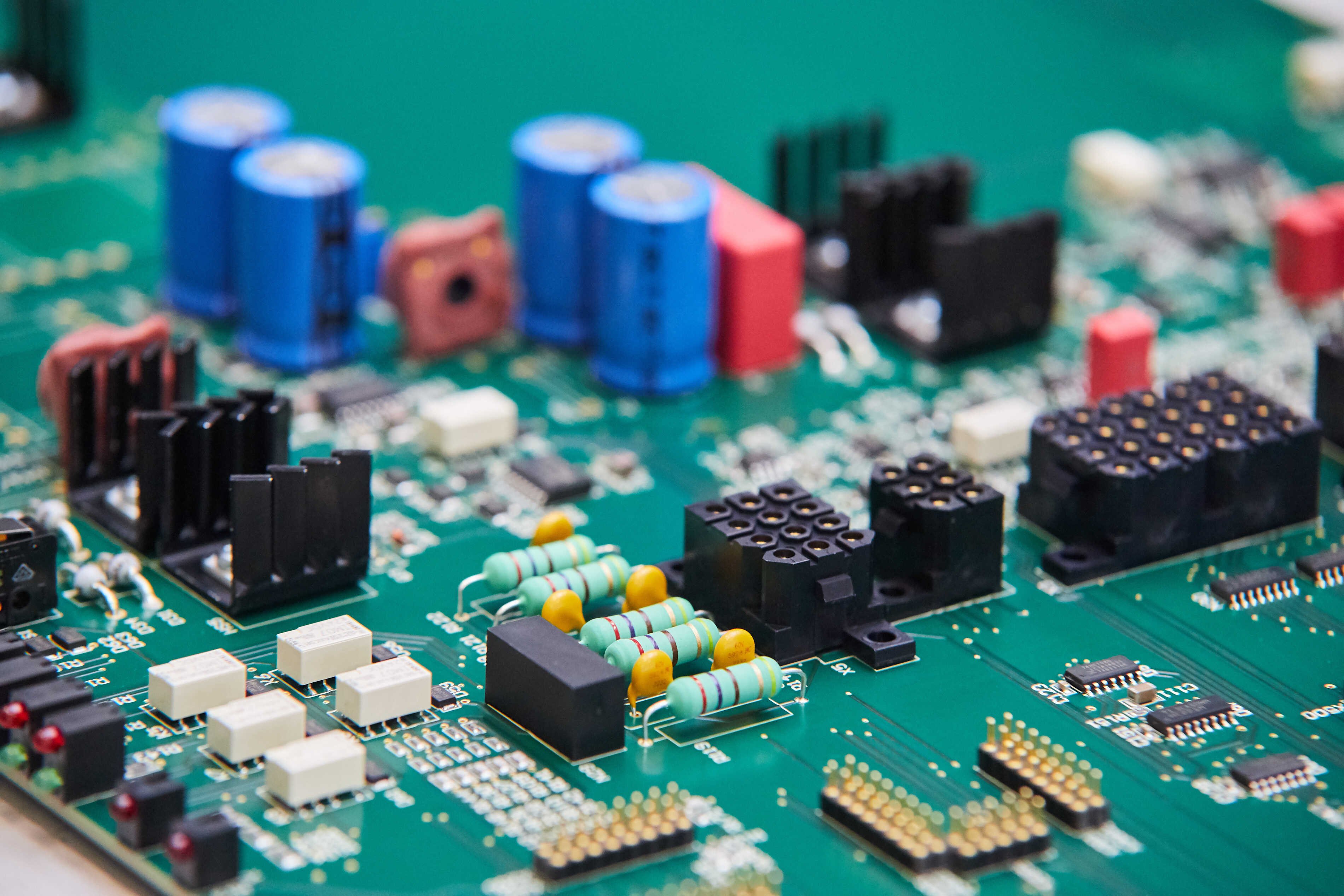

We want your idea to acquire realistic contours, connections and components. Safiral's leading characteristics include flexibility. In practice, we will assemble a prototype for you from just one piece.

Even one manufactured product can change the world

The prototype is the leading segment of our production. Based on long-term experience, we have optimized and simplified its implementation process and offer customers technical support and feedback from internal experts. Assembling prototypes in PCBA is usually the first iteration of a new product design. It serves as a way to test the functionality and performance of the board before moving to mass production.

Our electronics prototyping process is based on solid pillars:

- business relationship complemented by active communication

- speed and flexibility

- design iteration - management of design changes related to the location and availability of components or PCB technology

- output quality control by standard

- possible testing or revival of the board

- innovation in materials, functionality and design

- subsequent pre-series and series production

It's worth noting that cost is often considered when building a PCB prototype. While the sample aims to test and improve the product design, it is also essential to keep costs under control. Contact us to learn about low-volume manufacturing options that can help you keep costs low while still producing functional equipment.