Potting with two-component stuff is in compliance with demands on electronics protection against mechanical damage, external effects like humidity or chemical substancies, and against heat as it has very good thermal conductivity characteristics. Another positive feature of potting is a considerable complication in reverse engineering of a hard-ware product as the necessity of grinding off creates a certain barrier.

The only disadvantage is you can not repair the electronical module once it had been potted. This means you can do potting only with PCBs that had undergone complete electric and functional tests.

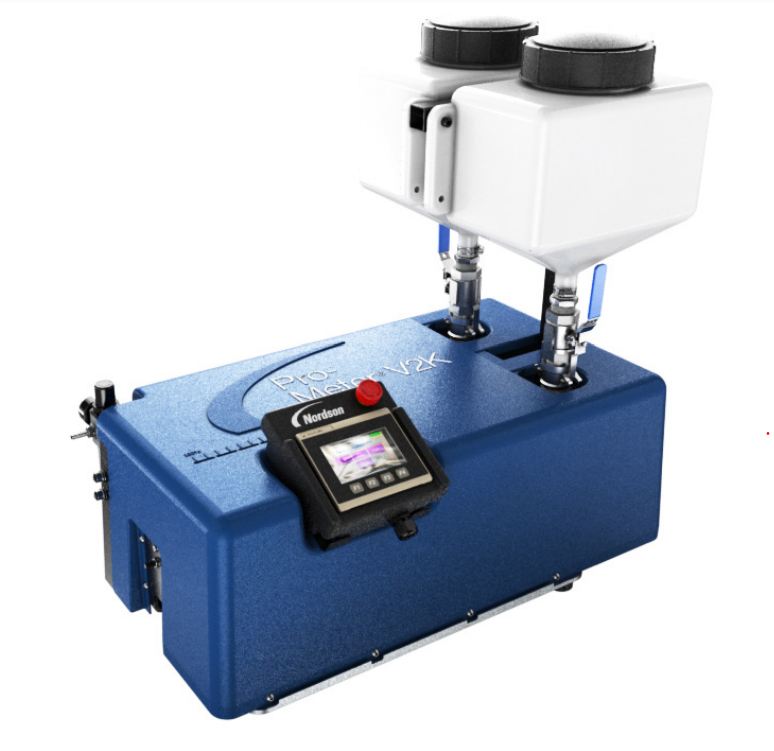

We offer our clients electronic testing on devices delivered by themselves (developer kits), on custom built adapters (needle-beds) or on Fying-Probe-Testers. For electronic potting we have chosen a black two-component polyurethan substance called RAKU-PUR® 21-2360-1 manufactured by RAMPF. We mix it and dose with a newly purchased device Nordson Pro-Meter® V2K in configuration with external containers including post-mixing and vacuuming the substance in the container. We have found a professional solution in line with our devices and technologies.